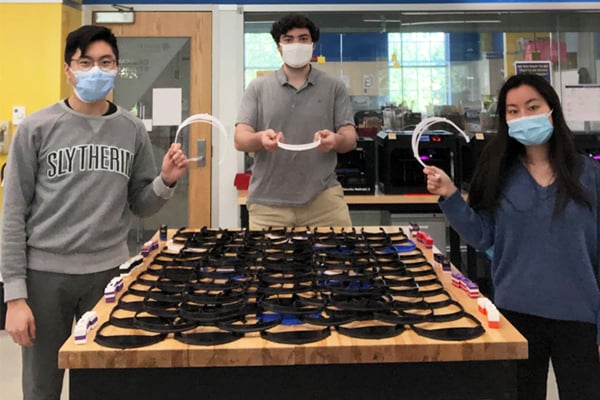

While most of his classmates were preparing for final exams and upcoming summer internships, Chris Shallal spent the end of his third year focused on a multi-campus effort to create and provide durable, reusable face shields to healthcare workers at the Johns Hopkins Hospital.

To help fill the hospital’s urgent need for personal protective equipment (PPE) due to the COVID-19 pandemic, the Johns Hopkins Consolidated Service Center (CSC) recruited volunteers to assemble disposable foam face shields. Shallal, a third-year biomedical engineering student, noted that the foam headbands used for these face shields do not hold up to prolonged wear, and must be disposed after a single use because the porous material could potentially trap hazardous particles. He and his fellow engineering classmates at Health 3D, a social venture that uses 3-D printing to improve healthcare products, submitted a proposal to the Johns Hopkins COVID-19 Research Response Program detailing their plan to manufacture a more durable headband that would allow face shields to be worn multiple times.

With the help of Elizabeth Logsdon, senior lecturer of biomedical engineering, and Warren Grayson, associate professor of biomedical engineering, the team’s proposal was accepted, and they were provided $10,000 to use toward printing materials. To make the headbands, the team is using extra-tough PETG filament, known for its strength and stability. It can be wiped down with basic cleaning agents such as isopropanol, bleach, or ethanol without affecting its durability.