In her final year as an undergraduate at USC, dancer Kaitlyn Kumar tore a ligament during a rehearsal for the ballet Sleeping Beauty — but powered through the pain to perform anyway, thanks to ample amounts of ibuprofen and Tiger Balm. “That’s just what dancers do,” she said.

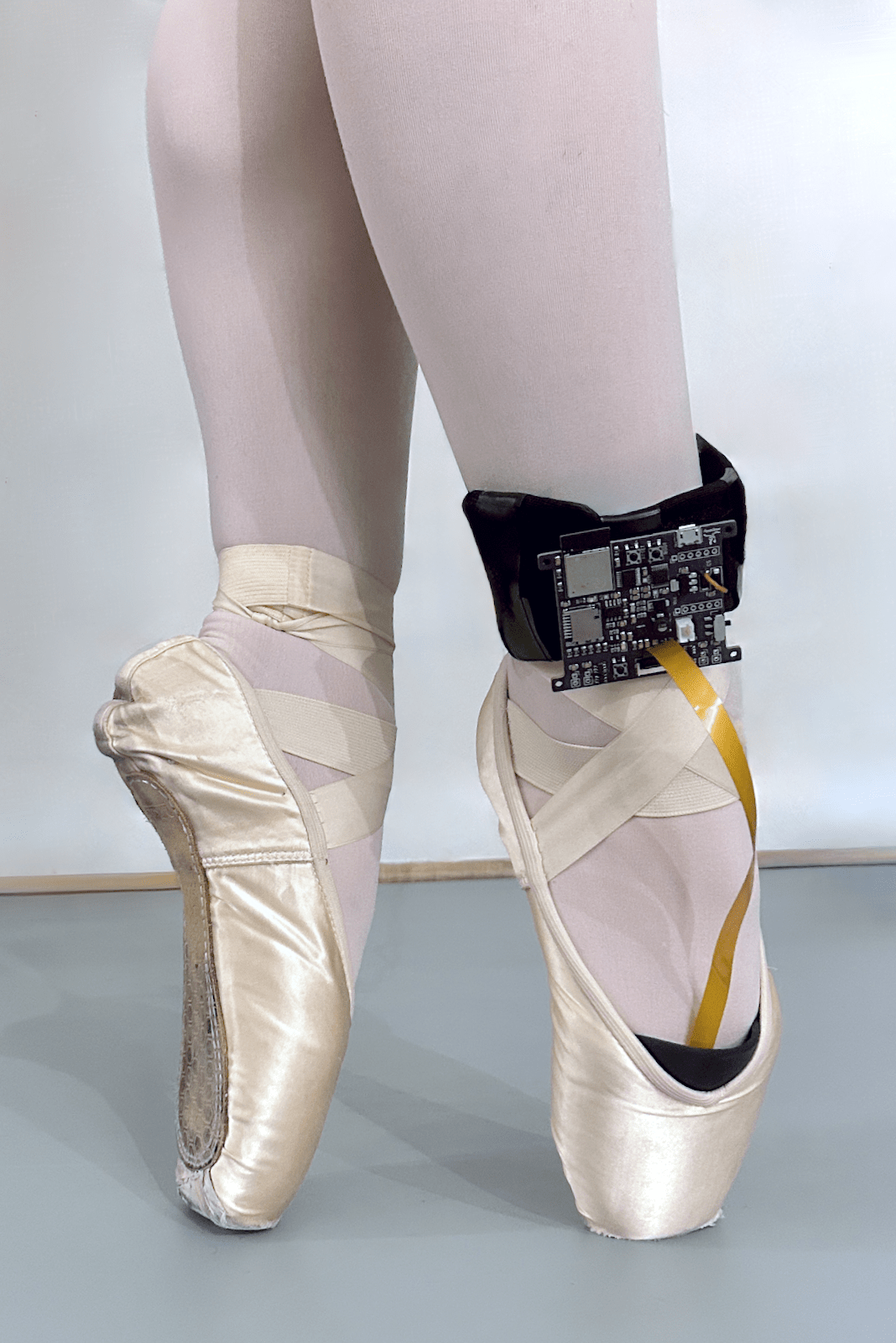

Now a master’s student in robotics at the Johns Hopkins Whiting School of Engineering, Kumar has turned her injury into innovation. She’s part of a student team developing PointeSense, a smart toe pad and ankle band designed to help prevent injuries in ballet dancers who perform en pointe—a demanding technique where the dancer balances all their weight on the tips of their toes.

“Our invention is placed snugly into a ballet pointe shoe and fitted with a series of pressure sensors,” said Kumar. “PointeSense helps dancers improve their pointe technique by detecting mistakes in real-time and using gentle vibrations to guide their feet into the correct position.”

Kumar co-invented PointeSense with fellow dancer and biomedical engineering major Christine Fernandez and biomedical engineering master’s students Daniel Campuzano and Bryan Sabogal, as a project in the university’s Principles of Design of Biomedical Instrumentation/Honors Instrumentation course sequence.

In the ballet world, injuries like Kumar’s are remarkably common, with eight out of 10 dancers experiencing some form of physical damage each year, from stress fractures and ankle sprains to toe and toenail injuries. While pointe work is an iconic feature of classical ballet, inadequate strength and improper form often lead to injury.